February 8, 2022

Building owners and operators continue to task HVAC engineers, contractors, and suppliers with finding creative solutions for complicated challenges. It’s no longer enough to find the least expensive means of providing heating and cooling. The solution

must also intuitively feel aligned with the future, considering long-term trends like decarbonization and electrification.

In 2020, utility-scale generation facilities in the U.S. produced about 4.01 trillion kilowatt-hours of electricity. Over 40% of this total was generated with natural gas, which has traditionally been one of the more economic means of generating heat.*

But experts now contend that the era of cheap natural gas is over, citing increased demand, and reduced investment in natural gas exploration and infrastructure. Plus, several states and municipalities are starting to limit — or prohibit —

the use of natural gas in new homes and buildings to help combat climate change. With gas prices and regulatory requirements on the rise, it may be more practical to generate heat with electricity. Enter heat pumps — which are capable of both

heating and cooling using only electricity.

Many commercial heating systems generate heat with natural gas, and they are about 80% efficient. Another way of stating this is that about 80% of the gas heat energy expended is delivered as heat to the space. By comparison, heat pumps can deliver up

to five times the heat energy expended to the space because they can move more heat energy from the ambient air into the space than the energy consumed to move that heat. I.e., they are up to 500% efficient.

While often faulted for being more expensive upfront, heat pump systems can provide heating less expensively in terms of operating costs.

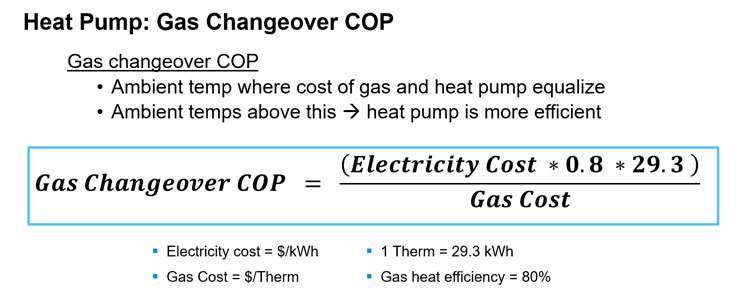

The obvious question is: At what outdoor temperature does using a heat pump instead of natural gas deliver ongoing savings? The industry refers to this calculation as the gas changeover coefficient of performance (COP). The changeover COP is the ambient

temperature where the cost of gas and electric heat pump operation equalize. Above the calculated gas changeover COP, the cost per unit heat to run a heat pump is less than that of a gas heater.

A hypothetical illustration may help. The equation pictured shows that when it’s 10 degrees Fahrenheit (10° F) or warmer outside, the heat pump can generate heat less expensively than a gas-driven alternative. You happen to know that the ambient

temperature in your area during October is typically greater than 10° F. You also know this is true of November, March, and April. Even in the months between November and April, you know there are several days where the ambient temperature exceeds

10° F. As a result of these simple observations, it’s evident that heat pump technology can lower operating costs.

A hypothetical illustration may help. The equation pictured shows that when it’s 10 degrees Fahrenheit (10° F) or warmer outside, the heat pump can generate heat less expensively than a gas-driven alternative. You happen to know that the ambient

temperature in your area during October is typically greater than 10° F. You also know this is true of November, March, and April. Even in the months between November and April, you know there are several days where the ambient temperature exceeds

10° F. As a result of these simple observations, it’s evident that heat pump technology can lower operating costs.

A building energy analysis can fully validate the annual energy savings of a heat pump. It is also important to note that local utility rates (gas and electric) heavily dictate the changeover COP. Yet, the formula is directionally useful and can yield

the creative insights that building owners expect. As gas prices rise (and the experts say they will), the case for choosing a heat pump system becomes even more compelling.

While a heat pump system can trim utility bills, it pays to understand a little bit about the various compressor types as well. Standard fixed-speed compressors, for example, can only operate at full capacity. Two-speed compressors are better and allow

operation closer to the heating or cooling capacity needed at any outdoor temperature. Far better is a variable speed inverter scroll compressor, found in equipment such as Daikin Applied Rebel packaged rooftop systems with an air-source heat pump.

Rather than continuously cycling between maximum capacity and zero (or low and high speeds), a variable-speed inverter scroll compressor continuously modulates its output in the background to provide a consistent temperature. It reacts congruently with

varying changes in heat demand, ensuring temperature fluctuations are kept to a minimum.

In effect, it operates more precisely to meet heating and cooling requirements, delivering higher energy efficiency ratios and lower costs. With inverter compressors and adaptive refrigeration technology, Rebel systems, for instance, provide best-in-class

efficiencies — up to 20.3 IEER, 43% higher than ASHRAE standard 90.1.